On October 30th, the T3 terminal and the fifth runway of Guangzhou Baiyun International Airport were officially put into operation, marking the beginning of the era of "five runways+three terminals" operation at Guangzhou Baiyun International Airport and becoming the first and largest single rest airport in China's civil aviation industry to have five commercial runways in operation.

This super airport, which carries the mission of being the hub of the Guangdong Hong Kong Macao Greater Bay Area, has once again been upgraded, opening up a new channel for the Bay Area to connect with the world with its majestic momentum.

Guangzhou Baiyun International Airport

Planned for 2045

Annual passenger throughput of 140 million people

Cargo and mail throughput of 6 million tons

The largest renovation and expansion project in the history of China's civil aviation airport construction

The newly built T3 terminal, as a key project in the national "14th Five Year Plan", is not only a terminal building, but also a giant comprehensive transportation hub integrating aviation, high-speed rail, intercity, and subway

The first airport in China to seamlessly connect "two high-speed railways and two intercity railways"

The first panoramic aerial observation platform and observation tower in China

The first airport in China to construct a large-scale public art system

The total construction area is 683300 square meters, and its unique design and craftsmanship have created multiple "firsts" in China, creating a new paradigm for Chinese airport terminals.

On the occasion of the world-renowned 'wings of the Greater Bay Area' spreading and soaring, the ERA pipeline has built a hidden and powerful 'bloodline system' for this world-class aviation hub with excellent quality and professional technology

Invisible Backbone

Building a resilient pipeline lifeline

As an important component of a super airport, the efficient operation of the main terminal and peripheral facilities relies on reliable pipeline system support. In the face of enormous carrying demands, extremely high safety levels, and long service life requirements, the pipeline system of ERA provides a critical solution.

01 Can the communication pipeline be stabilized in the complex and ever-changing climate of Shiceng?

In addition to the precise construction of the main terminal building and internal functional systems, the stability and efficiency of the communication network are equally crucial

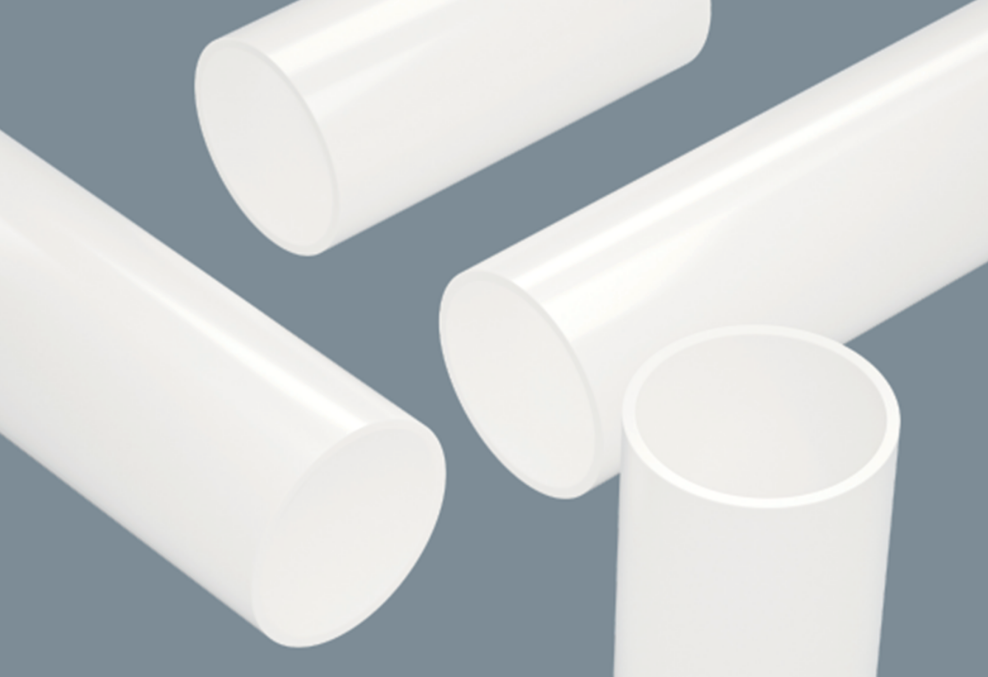

High performance PE solid wall communication pipes are known for their flexibility, impact resistance, and low temperature resistance, making them suitable for scenarios that require high environmental adaptability and long-term stability

The soil structure of the airport is complex, and the ERA PE solid wall pipe is flexible and impact resistant, with a fracture elongation rate of over 350%. This means that it has excellent toughness and its ability to stretch without breaking is much higher than ordinary pipelines. It can absorb and disperse external impacts through deformation, thereby avoiding pipeline damage and greatly improving its adaptability, resistance to damage, and overall safety

The climate in Guangzhou is humid and rainy, coupled with seasonal typhoons and ultraviolet radiation, ordinary pipes are prone to aging, cracking, or chemical erosion. PE solid wall pipes can be safely used in the temperature range of -20 ° C to 40 ° C, with stable chemical properties and long-term use. At the same time, through hot melt/electric melt connection, a fully sealed system is formed to ensure the safety of the pipelines.

In addition, the inner wall of the ERA PE solid wall communication pipeline is smooth and free of burrs, with an absolute roughness ratio of 1/20 of steel, greatly reducing the frictional resistance of optical cables during the threading process, and providing sufficient convenience for subsequent system expansion and maintenance.

02 High pressure water supply, how can the ERA pipe handle it?

In the airport stand expansion project, the underground pipeline network of the runway engineering needs to withstand high water pressure impacts from fire water supply, pressure sewage and other systems, while also dealing with complex load changes and long-term corrosion caused by aircraft takeoff and landing

The ERA steel wire mesh reinforced polyethylene composite pipe is formed by compounding high-strength steel wire mesh skeleton with high-density polyethylene, combining the flexibility of plastic pipes with the high strength of metal mesh. It can withstand high water pressure impact and perfectly adapt to the high-frequency and high standard operation and maintenance needs of airports.

The creep resistance and impact resistance of pipes effectively suppress the deformation of pipelines under stress, enhance their stability under complex loads and slight foundation settlement conditions, and ensure the long-term safe operation of pavement engineering.

Continuous empowerment of the power of the Common Era

From the magnificent cross sea appearance of the Hong Kong Zhuhai Macao Bridge, to the underground network of the Shenzhen Metro, from the grandeur of the Shenzhen International Convention and Exhibition Center, to the soaring development of Baiyun Airport today, the ERA pipeline has always resonated with the construction of the Bay Area.

From landmarks in the Bay Area to national strategic projects, from urban renewal to rural revitalization, AI Manufacturing is continuously integrating more "Chinese business cards". With over 40 years of deep accumulation in the pipeline field, we continuously output high-quality solutions through "product+service+culture".