On September 18th, Zhejiang Satellite TV's "Zhejiang News Broadcast" focused on the export performance of Zhejiang enterprises amid the Federal Reserve's rate cut, highlighting ERA's outstanding foreign trade performance.

The footage captured a bustling scene at ERA's foreign trade base, where batches of freshly produced pipe products were being loaded onto trucks for shipment to the United States. As one of ERA's most important overseas markets, ERA continues to strengthen its product, service, and brand presence in the US market, ensuring that "Made in China" continues to shine on the international stage.

Product strength is the foundation for a strong presence in the US market. In recent years, despite adjustments to US tariff policies, ERA has consistently driven development through technological innovation. Leveraging strong independent R&D capabilities and an efficient production system, ERA has established a consistently competitive edge in the US market.

Huang Huan, Deputy Sales Director of ERA Pipe Zhejiang Co., Ltd., stated in an interview: "The company maintains a keen eye on policy trends and mitigates potential risks by adjusting its production and delivery schedule." Starting in September, shipments increased by approximately 30% compared to normal, effectively offsetting the risks associated with the Federal Reserve's interest rate cuts.

More importantly, ERA is actively responding to changes in the US market and customer demand, ensuring order stability and growth through new product development. For example, the company has refined its product line of American-made drainage fittings tailored to the US market, fully covering the sizes and types required by the market, meeting all customer needs and further consolidating its market position. Currently, ERA's diverse product lines, including PVC and CPVC pipes, fittings, and valves, all comply with ASTM standards and have received international certifications such as NSF and UPC.

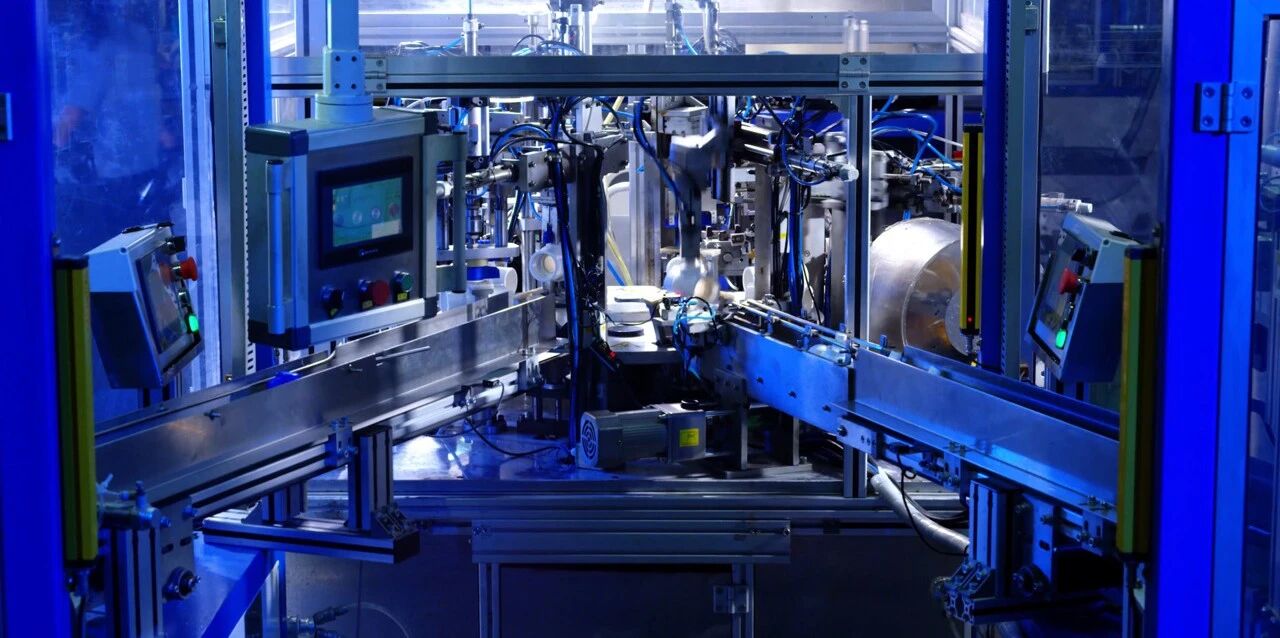

An efficient production system is a key component of ERA's response to challenges. In ERA's smart factory, automated elements such as robotic arms, robots, and automatic injection molding machines permeate every corner, achieving 100% unmanned operation. Furthermore, through upgraded production line operations, the company has transitioned from traditional separate production and packaging to integrated, in-line packaging within the workshop, improving production efficiency while reducing costs.

Service capabilities are key to maintaining a strong foothold in the US market. From registering the "ERA" trademark in the United States in 2000 to successfully establishing the IAPMO U.S. laboratory in 2018—the first and only such laboratory in the manufacturing industry at the time—to ERA's diverse product lines, including building and home improvement, selling well in major US supermarkets like HOMEDEPOT, Lowe's, and MENARDS, becoming the preferred choice for quality building materials... ERA manufacturing is becoming a competitive advantage in the US market, transforming from "manufacturing" to "smart manufacturing" and establishing a firm foothold.

Brand power is a key tool for expanding into the US market. ERA's presence can be seen everywhere, on online social platforms like Facebook and Linkedin, large-scale offline billboards, and e-commerce platforms with tens of thousands of products. In recent years, ERA has not only garnered sustained attention from central and provincial media outlets, but has also been featured on international platforms such as CGTN, highlighting the outstanding performance of Chinese companies in coping with tariffs. "ERA" is earning the trust and recognition of customers worldwide with its solid product quality and brand reputation.

In the future, ERA will continue to deepen its presence in the US market, leverage its product, service and brand advantages, respond to the challenges brought about by changes in the international environment with the confidence of Made in China, and demonstrate the resilience of Made in China to the world.