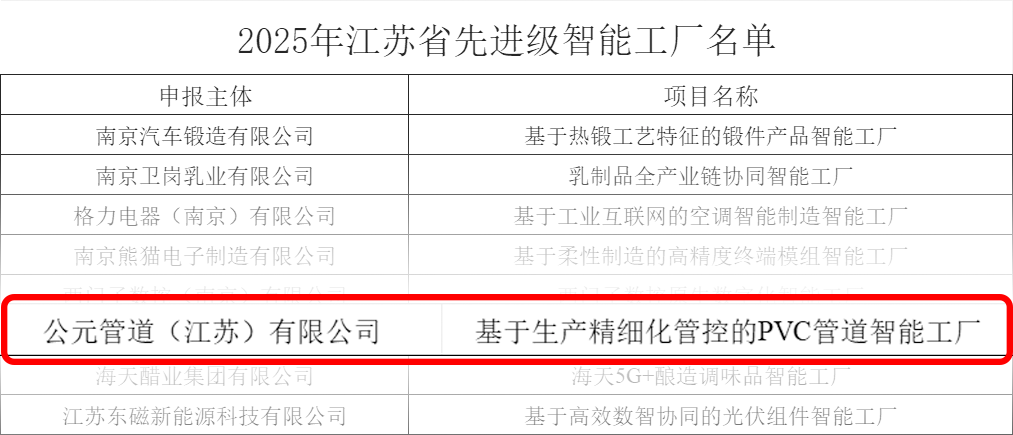

Recently, the Jiangsu Provincial Department of Industry and Information

Technology announced the "List of Advanced Smart Factories in Jiangsu

Province in 2025", and Jiangsu ERA was on the list.

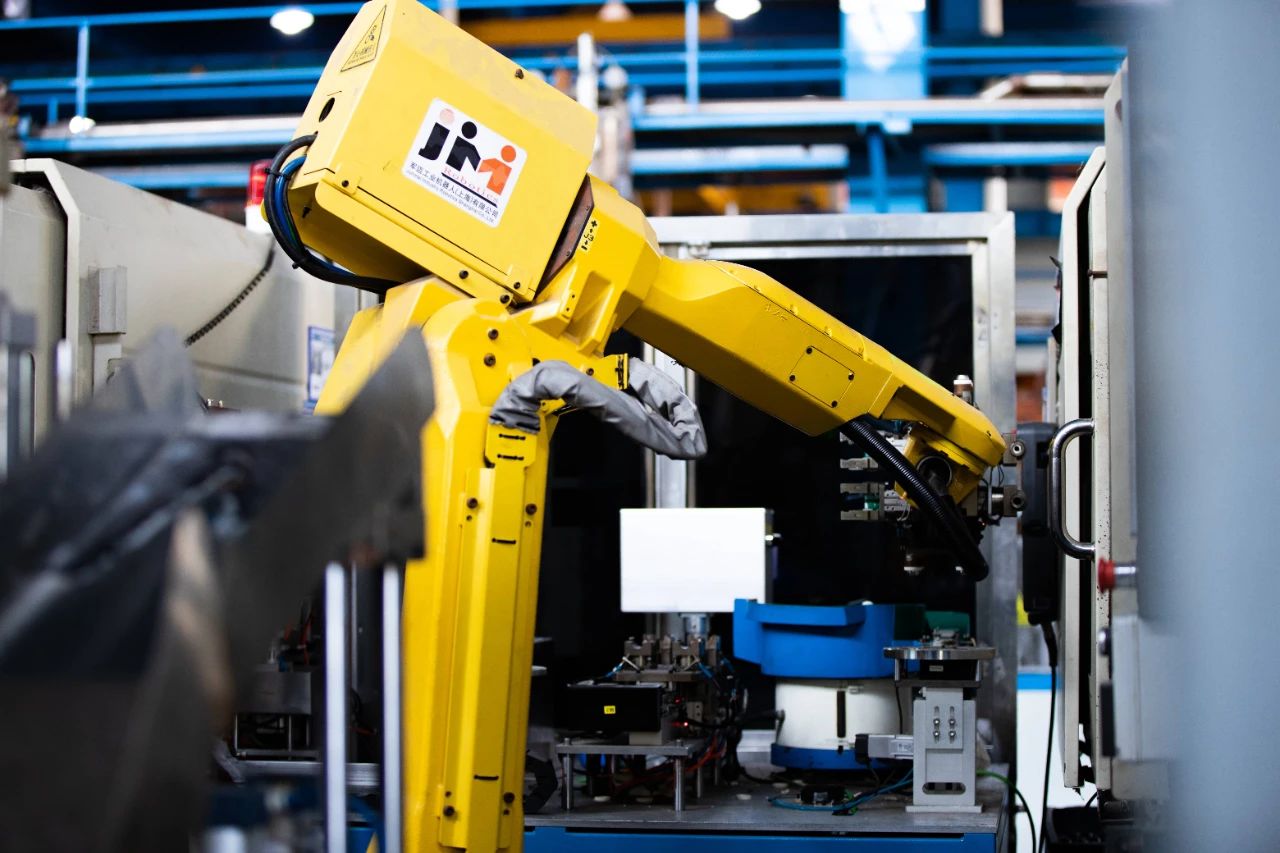

As the main carrier for realizing intelligent manufacturing, smart factories promote the

interconnection of production equipment and information systems

by deploying intelligent manufacturing equipment, industrial software and systems,

which is an important support for developing new quality productivity

and building a modern industrial system.

Jiangsu ERA is the ninth core production base of ERA Co., Ltd. in China

and was officially put into operation in 2023. During the construction process,

Jiangsu ERA focused on the three main lines of intelligent transformation of

manufacturing industry, digital transformation and network connection based on

refined production control, and took the gradient cultivation of smart factories

as the key to build a full-chain transformation system of "diagnosis

and evaluation-technology empowerment-scenario expansion-ecological construction".

It has achieved comprehensive optimization of the entire product life cycle,

the entire production and manufacturing process, and the entire supply chain,

as well as comprehensive improvement of efficiency and benefits.

Jiangsu ERA was awarded the honorary title of "Jiangsu Province

Advanced Smart Factory", which is another honor after ERA Co., Ltd. won the first batch of

"Zhejiang Province Machine Replacement Demonstration Enterprise" and

"Zhejiang Province Smart Factory" and Anhui ERA won the "Anhui Province Digital Workshop"

and other heavyweight honors in the manufacturing industry,

demonstrating ERA's extraordinary strength in smart manufacturing. In the next step,

Jiangsu ERA will play the role of an advanced benchmark for smart factories,

continue to promote the development of intelligent production and manufacturing,

intelligent operations, and low-carbon management, and create a "smart,

automated, information-based, and green" low-carbon sustainable enterprise,

providing ERA's "digital intelligence" power to accelerate the

high-quality development of the plastic pipe manufacturing field.